GE an update on IoT progress from Minds and Machines

GE is probably the global business most strongly associated with demonstrating not just a strategic commitment to IoT, but also for leading business driven implementations. The GE annual Minds and Machines event in San Francisco has become an Industrial Internet showcase for Business IoT. Packed with case studies demonstrating millions of dollars of business benefits, together with GE announcing its own next plans to derive business value from IoT adoption.

Minds and Machines has examples of real business strategic transformation case studies that are the game changes to industry sectors. Here GE, and other major Global Industrial Players, show how in Industrial Manufacturing IoT with Connectivity, Cloud Provisioning, and now AI delivers on major projects. Minds and Machines is not about ‘pilots’, or small Enterprise projects, it’s about how real Strategic Transformation has delivered millions of dollars of benefits.

As with Salesforce Dreamforce some weeks ago the manner of the event itself is significant. Technology wide support from speakers, sponsors and exhibitors demonstrates strong moves towards engagement and adoption of the approaches. Minds and Machines follows the trend towards events focusing on understanding the use of Technology in Business rather than product release hyping. As this is an event primarily about Industrial IoT the following sponsors from an IT background, (in addition to the expected Industrial players), says much about the merging of the technology market within IoT;

Highest Level; Accenture, Deloitte, Microsoft, HP, Intel

Second Level; Capgemini, E&Y, PWC

Third Level; Dell, Infosys

Only a year ago the different technology worlds didn’t seem to be aware of each others moves into IoT as detailed in the blog; IoT - where two or even three possibly four worlds collide or operational technology meets information technology. Now as deployments move to Enterprise scale the understanding of the need for broader integration into Enterprise IT systems has become clear. The list of technology sponsors is in fact a list of major SIs. However what used to be known as Systems Integration, or SI, would be better termed ‘Solutions Integration’ to match the widening of skills required across multiple disciplines.

So the answer to the question posed in the blog IoT – where are the Integrators, or more particularly who are the Integrators? seems to be arriving. The global SI players who have grasped the need are making themselves known at key IoT events that enable them to demonstrate their case studies. (As are an increasing number of small-specialized players who have chosen to specialize in IoT integration).

As ever the challenge remains as the number of skilled staff available at any of these companies, so there is a necessity for a high degree of focus in the activities of any of the SI players. As Solution Integration of IoT carried out by specialized units within the overall Systems Integration business it is difficult via the usual sales and account management channels access the level of information that will help find the right SI for your requirement.

Large scale specialized IoT exhibitions, such as Minds and Machines, have come into their own during this last year. When it’s difficult to pinpoint what you want and, frustrating to try to get access to the real skilled staff, the simplicity of an exhibition has become appealing. The IoT market is laid out for physical browsing with the benefit that you can walk onto stands of interest to question knowledgeable staff, usually in the presence of a full-scale demonstration. It’s pretty easy to see why exhibitions are back in favor with remarkably high attendances are being reported at the prime events!

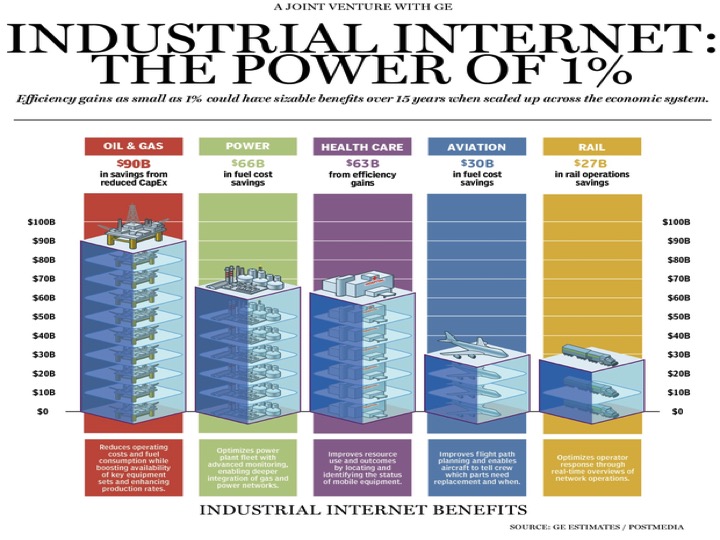

Minds and Machines delivers on this promise, as a showcase for the Industrial Internet, leading the way in show casing the development of Industrial Automation and Operational Technology. The case studies and presentations, particularly by GE themselves, all reflected on their premise of the 1% Improvement in five selected Industry sectors through IoT led Business Transformation.

A Brief Overview on the progress of GE Predix and GE Software;

These five Industry sectors are core markets for GE where many years of involvement have built up expertise in all aspects of the Industry sector. Each has similar characteristics of complex, sophisticated products, operated at scale, with large costs, making the simplicity of the focus and target of 1% costs saving a clear business strategy that would be understood by Boardroom executives.

The result has been considerable Boardroom interest with the resulting Industrial Internet collaboration in the USA, and in Europe the similar but slightly different parallel establishment of Industrie 4.0 .

It is difficult to overview the many case studies presented, (here are some from GE website), but there can be little doubt that the goals of ‘The Power of 1% Percent’ are on their way to being realized. (For more information see MIT Sloan’s review on GE strategic bet and Industrial Internet Case Studies from members). The next stage after the highly target improvement of GE products performance in the 1% strategy is to address the operation of their products as an ecosystem. The Rail Industry was one of the first targets for this level of Industry Transformation of overall operations as described in a GE Report dated March 2016.

GE strategy to achieve Industry Transformation across five key sectors rests on GE Predix its own in-house development using the expertise gained in the design and production of Industrial machinery. GE defines Predix as an operating system, or Platform for machinery. Predix combines the standard IoT ingredients; the connectivity of the Internet, the sensing of IoT, with Cloud provision; with the specialized characteristics of required for Operational Technology and specialized Modeling of industrial products and systems. Achieving the 1% savings goal across five major Industry sectors is big target so signing Predix alliances to train significant numbers of staff in the deployment of GE Predix in the big SIs that were in attendance is a critical success factor.

Predix has not surprisingly attracted a lot of attention, not always completely favorable with Fortune Magazine sounding a cautionary note in July 2016. Describing GE Software as a ‘baby startup’ Fortune pointed out as that in common with other startups the product wasn’t always as complete or robust as the marketing made it sound. In particular the article drew attention to the relatively poor ‘final mile’ connectivity, though these are the aspects that a Solution Integration partner should deliver.

In addition to its own considerable efforts to add capabilities GE has also been strengthening Predix by acquisitions; Asset Management expert Meridium in September, Machine Learning startup specialist Wise.io in October and now Field Service Manager ServiceMax in November. These moves taken with the final and all important fact of significant success in real deployments all suggest Predix has enough maturity to deliver commercial value.

In any Industrial Internet, or Industrie 4.0, event that relates to manufacturing, servicing, and operation of complex machinery, the topic of Digital Twins will be on the agenda. The extension of computer based design processes through 3D preproduction models to test expected performance, economy and maintenance operation into acting as an ongoing reference model, or Digital Twin, is becoming a reality. GE originally played a leading role in the definition and use of Digital Twins, though today there it is a widely accepted and supported concept.

Linking a Digital Twin model by means of IoT sensing to the real physical machine provides both a direct comparison between the predicted behavior, and actual experience. The feedback to improve design, predictive maintenance and continuous operational optimization is a huge game change to the capabilities of Product Lifecycle Management, PLM, and will be the subject of a separate blog.

Minds and Machines is a unique view on how manufacturing and Service operation is and will be changed in the Digital Services economy. To fully understand the GE point of view of IoT and associated technologies impact on GE and its business then there is a copy of Bill Ruh SVP & Chief Digital Officer GE, and CEO GE Digital presentation here.